Structural adhesive bonding is a revolutionary technique in auto body work, particularly for electric and hybrid vehicles. It utilizes specialized adhesives to create strong, lasting bonds between various components, improving structural integrity, reducing weight, and enhancing aesthetics. This method allows car body shops to achieve precision and efficiency in complex repairs involving materials like aluminum, carbon fiber, and composites. By minimizing waste and simplifying repairs, it contributes to a more sustainable auto industry. Best practices in adhesive use and curing ensure longer-lasting repairs and improved vehicle quality. Advancements in materials science are driving the development of high-performance adhesives for challenging surfaces, aligning with the increasing use of composite materials and smart adhesives that can self-heal or adapt to environmental changes.

In the realm of electric and hybrid vehicle repairs, Structural Adhesive Bonding (SAB) is revolutionizing manufacturing processes. This cutting-edge technology offers lightweight solutions, enhancing safety and performance while reducing energy consumption. SAB’s benefits include improved structural integrity, fast curing times, and superior bond strength, making it ideal for complex vehicle components. This article explores the fundamentals, real-world applications, and future prospects of SAB, providing insights into its role as a game-changer in automotive repairs.

- Understanding Structural Adhesive Bonding: The Basics and Benefits for Electric and Hybrid Vehicles

- The Role of Structural Adhesives in Repair: Case Studies and Best Practices

- Future Trends and Innovations in Structural Adhesive Bonding for Automotive Industry Applications

Understanding Structural Adhesive Bonding: The Basics and Benefits for Electric and Hybrid Vehicles

Structural adhesive bonding is a revolutionary technique transforming the landscape of auto body work, particularly for electric and hybrid vehicles. Unlike traditional joining methods, it involves using specialized adhesives to create strong, lasting bonds between various components. This advanced approach offers numerous benefits, including improved structural integrity, reduced weight, and enhanced aesthetic appeal in vehicle body shops.

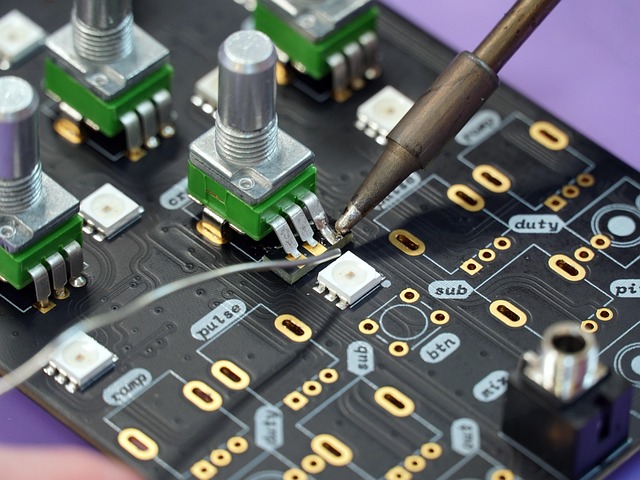

By adopting structural adhesive bonding, car body shops can achieve precision and efficiency in complex repairs. The method’s versatility allows for the seamless integration of different materials commonly found in modern vehicles, such as aluminum, carbon fiber, and various composites. This is crucial given the intricate designs and lightweight materials used in electric and hybrid cars. Additionally, the process contributes to a more sustainable auto industry by minimizing the use of mechanical fasteners, thereby reducing waste and simplifying the overall vehicle body repair process.

The Role of Structural Adhesives in Repair: Case Studies and Best Practices

Structural adhesive bonding plays a pivotal role in modern vehicle repairs, particularly for electric and hybrid vehicles, where precision and durability are paramount. This advanced technique involves using specialized adhesives to join components such as body panels, frameworks, and interior parts, offering a robust alternative to traditional fastening methods.

Case studies demonstrate that structural adhesive bonding can significantly enhance the structural integrity of vehicle restoration and collision repair services. For instance, in auto body repair involving complex geometries, adhesives provide seamless bonds, ensuring the vehicle meets safety standards. Best practices dictate using high-quality adhesives suitable for specific materials and environments. Thorough preparation of surfaces, including cleaning and profiling, is essential to achieve strong adhesive bonds. Additionally, proper application techniques and curing conditions ensure optimal performance, leading to longer-lasting repairs and improved overall vehicle quality.

Future Trends and Innovations in Structural Adhesive Bonding for Automotive Industry Applications

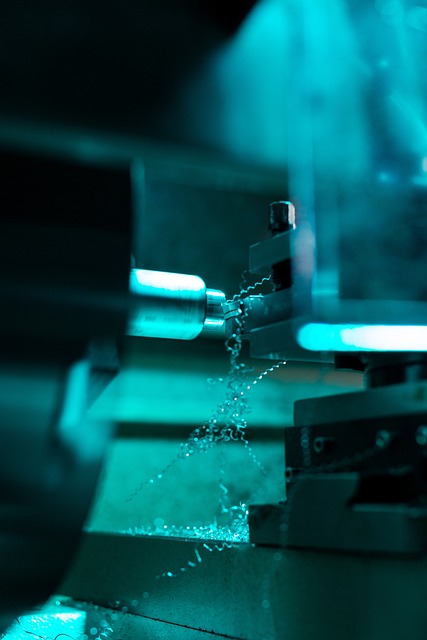

The future of structural adhesive bonding in the automotive industry looks promising, with continuous innovations pushing the boundaries of what’s possible in vehicle repairs. Researchers and manufacturers are exploring advanced materials and techniques to enhance the performance and durability of bonds, particularly in electric and hybrid vehicles. This includes developing high-strength adhesives that can withstand extreme temperatures and corrosion, ensuring safety and efficiency in these cutting-edge automobiles.

With the growing demand for sustainable and lightweight vehicles, there’s a shift towards using more composite materials in car body restoration and bodywork services. Structural adhesive bonding plays a pivotal role here by allowing precise assembly and seamless integration of these complex components. Innovations like smart adhesives that can self-heal minor cracks or adapt to changing environmental conditions will further revolutionize auto detailing processes, making them more efficient, cost-effective, and environmentally friendly.

Structural adhesive bonding has emerged as a game-changer in the automotive industry, particularly for electric and hybrid vehicles. By offering enhanced strength, lightweight construction, and efficient repair solutions, this technology is revolutionizing vehicle manufacturing and maintenance. As we look ahead, ongoing research and development in structural adhesives will further improve their performance, expanding their applications and contributing to more sustainable and robust electric mobility.